The 7-Minute Rule for Motorcycle Parts New Zealand Specialists

Table of ContentsSome Known Details About Motorcycle Parts New Zealand Specialists The 15-Second Trick For Motorcycle Parts New Zealand SpecialistsIndicators on Motorcycle Parts New Zealand Specialists You Should KnowFacts About Motorcycle Parts New Zealand Specialists UncoveredThe smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Talking AboutWhat Does Motorcycle Parts New Zealand Specialists Do?Our Motorcycle Parts New Zealand Specialists IdeasAll About Motorcycle Parts New Zealand Specialists

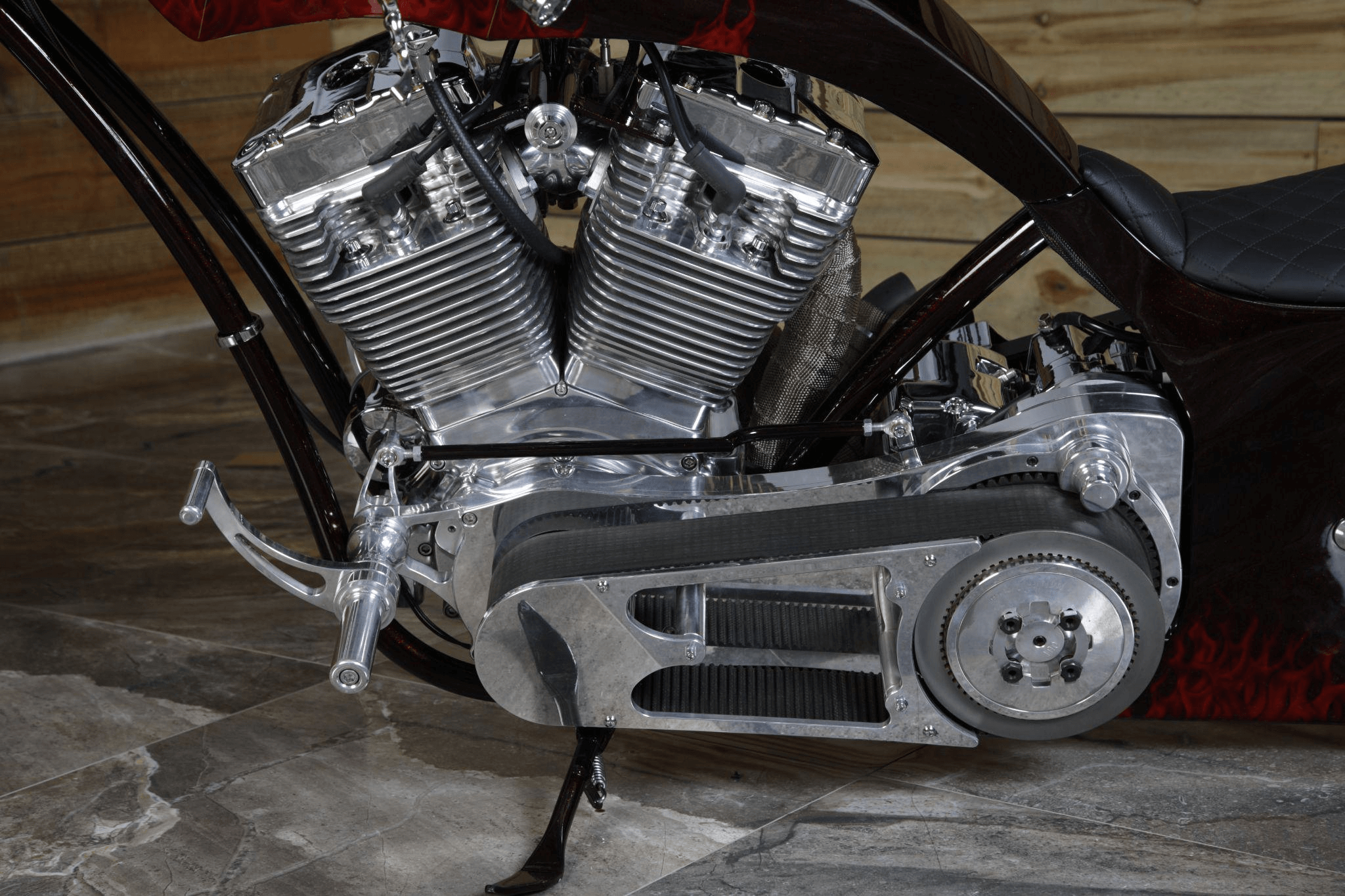

So, connect to among our experts today.CNC machining modern technology is quickly becoming the focal factor of several production processes around the world as a direct outcome of its many advantages over other methods. In addition, the markets that make bikes have jumped on board with this fad. One of the most cutting-edge companies are currently creating their engine elements and wheels using machining strategies initially developed for motorbike parts.

On the other hand, the results of sector are the main emphasis of this post. Let's get right right into it. You may be asking yourself why we use. It is not difficult to fathom the variables that resulted in this result. Currently that we have your attention let us clarify the reasoning behind this modern-day growth in the motorcycle manufacturing sector.

Not known Details About Motorcycle Parts New Zealand Specialists

On top of that, you have total control over the appearance of the elements, also to the minute information. Occasionally, motorcyclists might make a decision to fix up their trip by setting up aftermarket components or customizing the bike's transformation. Once more, computer system mathematical control (CNC) machining is the most practical approach. Upgrades might be of any form and style you want.

The Single Strategy To Use For Motorcycle Parts New Zealand Specialists

CNC machining may be used to make virtually all of a motorbike's metal and plastic elements. To proceed, we'll discuss several machined parts for motorbikes.

When tailoring the wheels, the disks are where the emphasis must be. The bulk of them are made out of aluminum. Aluminum alloys are widely known for the impressive machining capacities that they have. Milling treatments are used to obtain the wanted level of wheel customization. Another aspect of the motorbike that might be individualized is the tires.

The 7-Minute Rule for Motorcycle Parts New Zealand Specialists

When it pertains to an automobile (or a motorcycle), one of the most vital component is the engine. A number of individuals allude to it as the "heart" of the vehicle. On the other hand, the camshaft, the cylinder head, and the pistons often tend to be intricate and need designs with a high level of precision.

Usage just top notch items, nonetheless, considering that these lights are critical for the safety of motorcyclists and other motorists or individuals on the roadway, specifically at evening. Motorcycle headlights have three major parts: the bulb, or light resource, the lens, and the real estate.

Milling processes with a flawless surface would cause the lenses having a reflective high quality that is comparable to that of a mirror. The cover, on the other hand, is not composed of delicate products; rather, it is built out of challenging polymers that can be machined into more detailed patterns.

Motorcycle Parts New Zealand Specialists - The Facts

They typically have fancy geometries with a wide range of minute details. Bike makers frequently cast these components, but just for the manufacturing of bespoke parts. Nevertheless, CNC machining is the technique of option when producing one-of-a-kind pieces. Machining on five axes in today's world is the methods through which any style form may be realized.

Pick Runsom for your customized motorbike components! We have the capability to make challenging and trendy components making your motorbike incomparable.

Right here are a couple of instances of steels frequently utilized in motorcycle component machining. Light weight aluminum is the primary product made use of by companies specializing in creating personalized motorcycle components to create a lot of these parts. In the past, we would certainly build our engines out of cast iron. On the other hand, light weight aluminum next is quickly ending up being the material of choice, partially due to the truth that it is extra light-weight.

Zinc describes an their website additional steel that is really light in weight and has great machining top qualities because of its high mechanical strength. This product may be created into practically any type of shape and maintains its measurements well. Even mission-critical parts that need a high level of precision might gain from their use.

The smart Trick of Motorcycle Parts New Zealand Specialists That Nobody is Discussing

One more steel that sees hefty usage in the production of CNC-customized parts is magnesium. It is amongst the lightest steels that are currently obtainable and has exceptional machinability features and strength appropriate with its low weight. Among the disadvantages of magnesium is that its dirt might quickly catch fire.

Their most typical use in creating different motorcycle parts is fasteners, such as screws and screws. Their reduced sensitivity to oxidation and corrosion makes them suitable for this use.

Motorcycle Parts New Zealand Specialists Can Be Fun For Everyone

It appears that CNC turning and crushing are the foundational processes. In enhancement, it requires keeping bars of product, most often plastic or steel, in position and then twisting a cutting tool to get rid of areas of the material as the product is turned.

These techniques are similarly vital and create elements with high accuracy and consistent high quality. The processes help enhance the overall quality of the machined bike elements.

Motorcycle Parts New Zealand Specialists Things To Know Before You Get This